USM RESEARCHERS DEVELOP ‘SMART SOLDry HOME’ TO PRODUCE HIGH-QUALITY DRIED COWHIDE

NIBONG TEBAL, 14 November 2025 - A team of researchers from Universiti Sains Malaysia (USM) has successfully developed an Internet of Things (IoT)-based smart drying system called Smart SolDry Home, specifically designed to produce high-quality dried cowhide for the food industry.

The social innovation system was developed by researchers from the School of Mechanical Engineering (SoME) in collaboration with the National Poison Centre, the School of Biological Sciences, and industry partners Iotegrity Engineering and Ayden Food Solutions.

According to the project leader, Ir. Ts. Dr. Muhammad Hafiz Hassan, the system was designed to replace traditional open-air drying methods, which take two to three months and are prone to dust, insects, and unpredictable weather.

He explained that Smart SolDry Home offers a closed drying process that is cleaner and safer, with real-time monitoring of temperature, humidity, and weight using IoT technology.

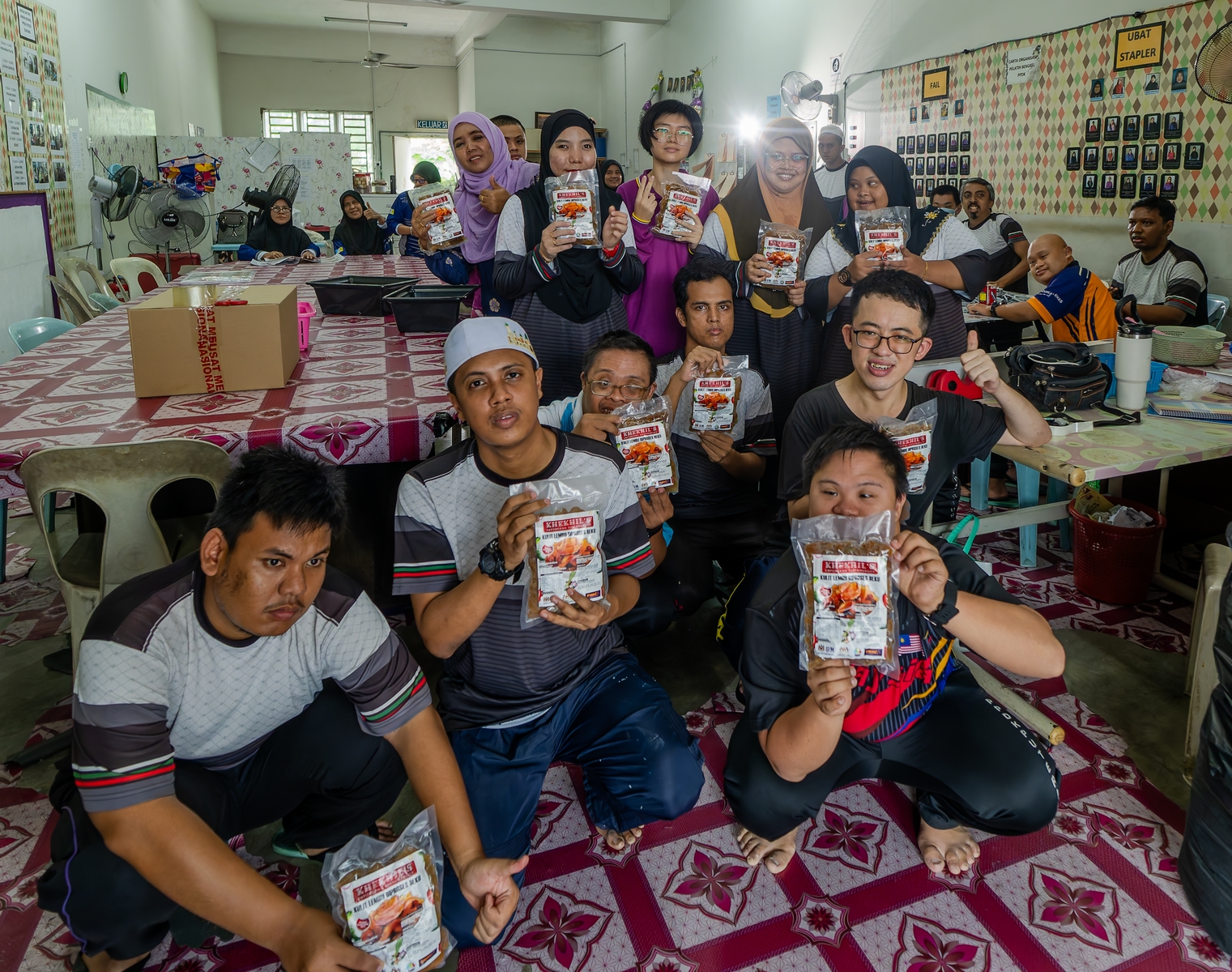

“The system can reduce the drying period to about a month, boosting productivity and helping local communities meet market demand for products such as Kekel (cowhide) and Sambal Taun under the KHEKHIL’S brand,” Dr. Hafiz said.

“Smart SolDry Home demonstrates how mechanical engineering technology can directly impact society, strengthen the economy of the PPDK Puteri Gunung community, and serve as a model for social innovation projects with potential for future expansion,” he added.

Dr. Hafiz also noted that the project, valued at RM199,400, was funded through the MyIS (MyIS-23-1028) grant under the Malaysian Innovation Foundation and represents a collaborative initiative between the university, industry, and the community.

He also added that the dried products produced through this system have also obtained Halal certification from JAKIM in July 2025.

The prototype development began in January 2024 and was completed in March 2025, after which the single unit was handed over to the Pusat Pemulihan Dalam Komuniti (PPDK) Puteri Gunung in Penang.

The project beneficiary, Suriati Hashim from PPDK Puteri Gunung, said the innovation opens new opportunities for trainees to acquire additional skills and venture into entrepreneurship.

“Smart SolDry Home has greatly helped our trainees understand how waste materials can be transformed into clean, safe, and commercially valuable products,” she said.

Suriati added that the system also provides income-generating opportunities for the PPDK Puteri Gunung community, and the organisation highly appreciates the contributions from USM and the Malaysian Innovation Foundation.

Apart from Dr. Hafiz, the project also involves core team members including Dr. Nur Azzalia Kamaruzaman (National Poison Centre), Dr. Amira Suriaty Yaakop (School of Biological Sciences), Ir. Dr. Abdul Haadi Abdul Manap (SoME) and Associate Professor Dr. Khairudin Mohamed (SoME).

A video related to the Smart SolDry Home project can be viewed at the following link: https://youtu.be/nz5F6-BaAP4?si=UEa9JWMAEXinF4VL

Text: Siti Faizah Abd Halim / Photo: Courtesy of Ir. Ts. Dr. Muhammad Hafiz Hassan